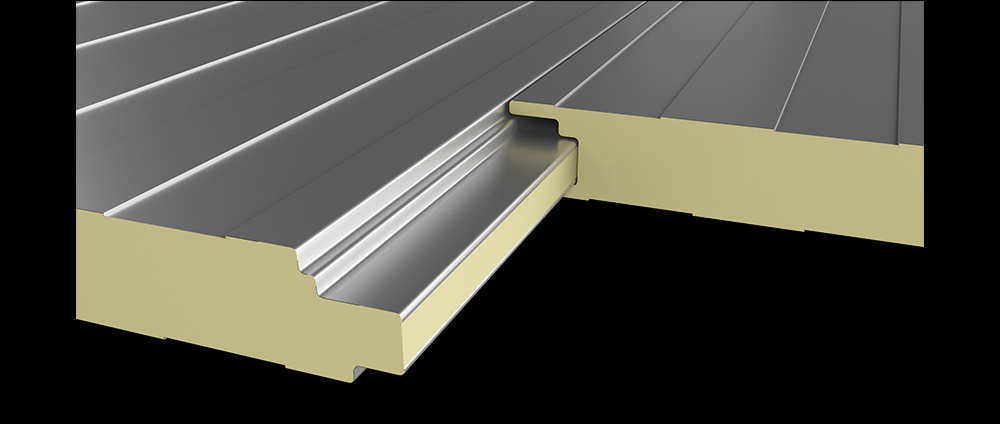

Micro Ribbed Hidden Screw Facade Panel-Pur

ÜRÜN DETAYI

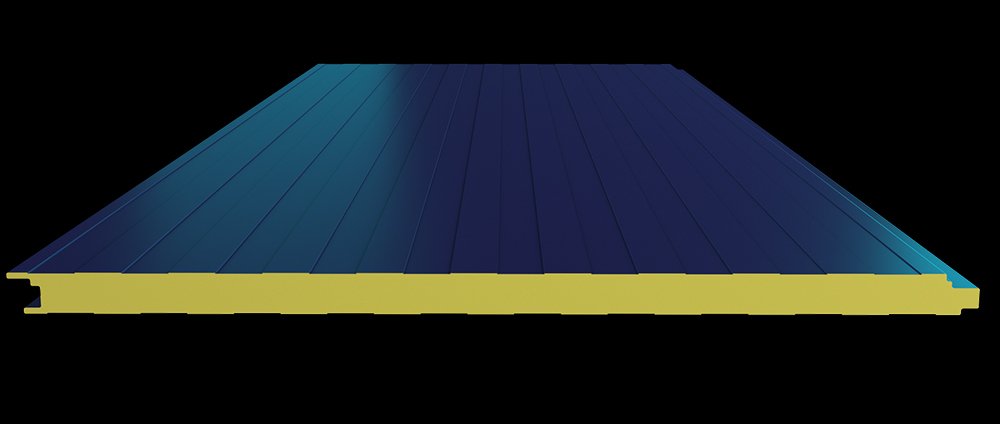

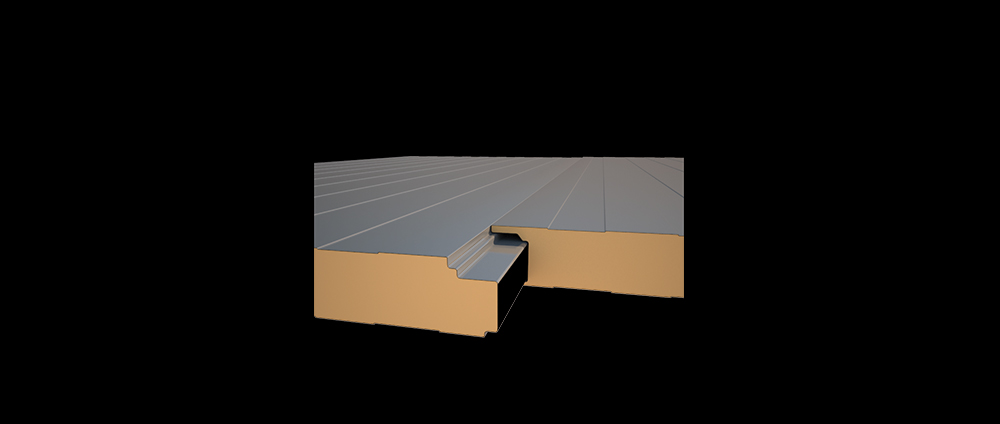

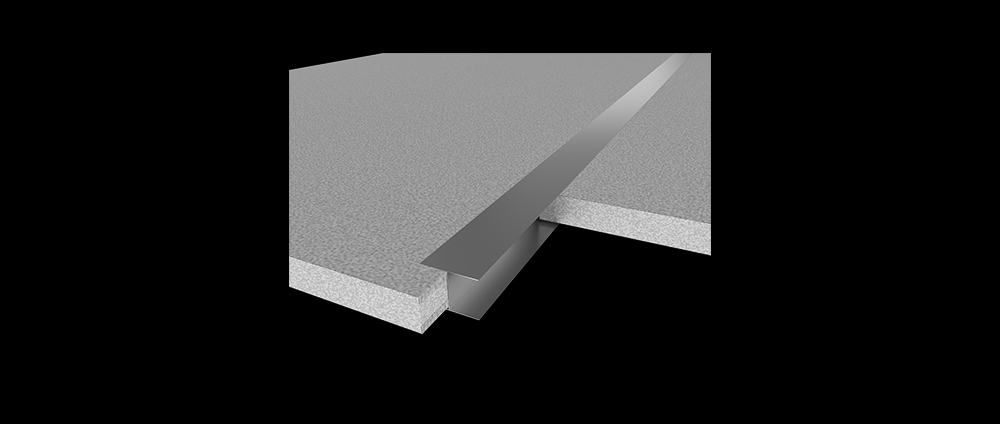

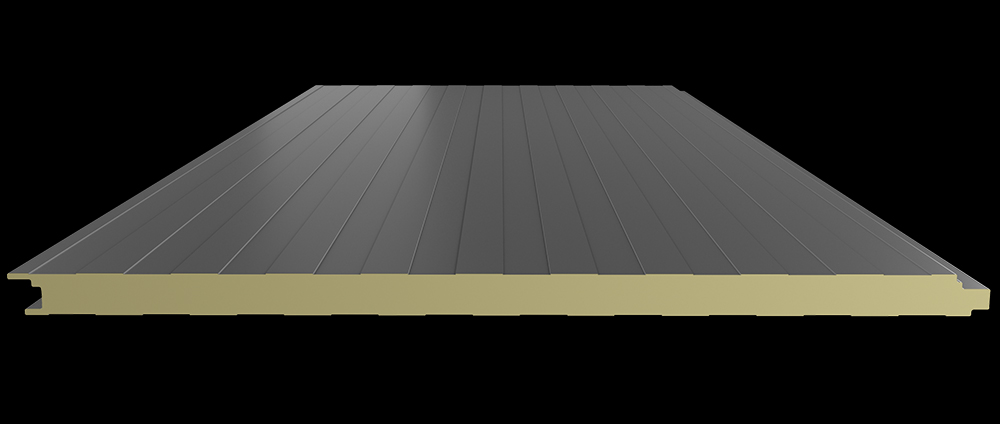

The hidden screwed polyurethane insulated facade panel has a lance system in terms of form. They are the most widely used sandwich panels among facade cladding panels. Facade panels made of micro rib and herringbone can be produced in different properties in terms of thickness and color. As the thickness increases, the bearing capacity and thermal insulation increase.

Standard facade panels insulated with polyurethane can be installed horizontally and vertically. Unlimited additive coating can be made up to 16m in vertical and horizontal. Horizontal and vertical lifting devices are different during assembly. Horizontal mounting can be simpler than vertical mounting.

It is possible to make factory building facades in different colors as a result of painting the painted metal covering the surface of polyurethane insulated facade sandwich panels in different color tones in roll form. Thanks to the developing technology, it has become easy to color the buildings today, which can be painted even in low m2.

Metal thicknesses differ in facade panels. The requirements of the project constitute the main factors that determine these differences. Facade purlin spacings used in the building in the project are among the factors that affect the thickness of the metal of the panel. If the facade purlins spacing is excessive, the panel should be increased in metal thickness. As the metal thickness increases, the ability of the panel to withstand wind load increases.

Increasing the strength in facade panels is not only provided by increasing the thickness of the sheet metal. Increasing the polyurethane insulation will also increase the strength of the panel. Polyurethane insulation thickness can be determined according to the plans of preserving the thermal values required by the project. The information to which metal and polyurethane will be thickened and thinned is a situation that will be determined by mutual agreement of project engineers and panel manufacturers.

Polyurethane insulated facade panels have been observed to have swelled in the past. These swellings occur when the panel surface heated by the sun is pressed on the metal by increasing the pressure of the gas contained in the polyurethane. To avoid this situation, manufacturers have developed a lamination of special strong adhesives before blistering in the polyurethane production line. Thanks to this special bonding situation, swelling of the facade panel surfaces is prevented by resisting the pressure of the gas in the polyurethane. It can preserve its appearance for many years without damaging its structure.