Hidden Screw Sinus Facade Panel Pur

PRODUCT DETAIL

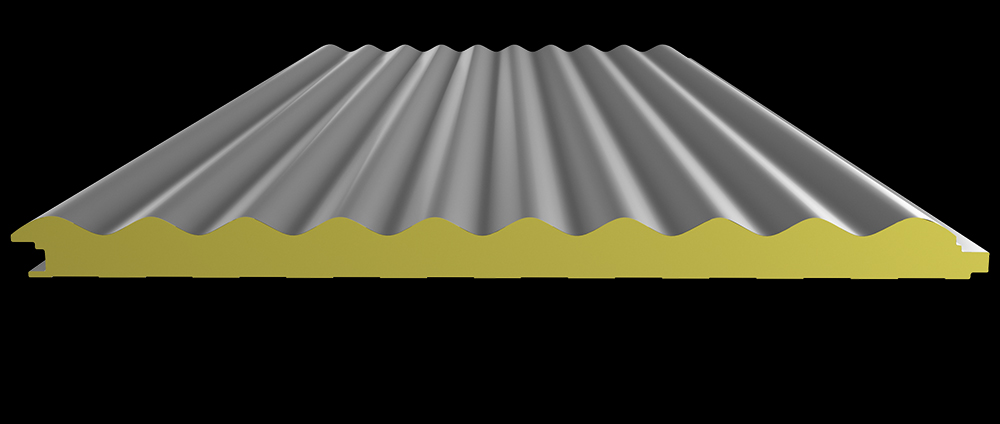

The full sinus façade panel is sinusoidal in form. They are sandwich panel systems with polyurethane insulation in the middle and painted galvanized sheet metal. The full sinus facade panel, which is installed horizontally and vertically, provides a modern appearance to the buildings. It is among the newest systems among facade panels.

Painted sheet, which takes the shape of a sinus in role forms, takes its final form in the oven by injecting liquid polyurethane. Full sinus facade panels that can only be produced with polyurethane insulation pass into each other. Polyurethane density can be max 38 kg/m3. The mounting screw is hidden in the space between the paneling system. In this way, the screws used during assembly are not visible from the outside. Since the mounting screws are not visible from the outside, a smooth surface is obtained.

Polyurethane insulated sinus facade panels are mounted on each other. In this way, an uninterrupted sinus form is provided in the facade cladding. The outer metal surface can be painted with the colors in the ral chart. It can be used in different color combinations in facade coatings. Different color combinations provide a personalized look on the facade of the building.

In the sinus form facade panels, which are the most preferred in architectural studies, accessory forms should be produced specially according to the panel feature. Since it has a protruding surface due to its form, the accessories to be used may not be properly assembled due to improper dimensions and shapes. Or there may be situations where the assembled accessory is not suitable for the panel form. Therefore, it is beneficial to pay attention to the shape and size of the complementary accessory systems to be used.

Sinus facade panels can be produced in desired insulation thicknesses as in other facade panels. As the panel infill thickness increases, the ability of the sinus facade panel to resist facade forces increases. In addition to the thickness of the insulation, the shape of the sinus is one of the factors that gives the panel strength. Sinus form increases the bearing capacity as the effect of the pitches on the roof panels. In this way, it ensures that the belts to be used on the facade surface are used less. This situation provides both lightness and economy to the structure.

As well as the thickness of the polyurethane insulation of the sinus facade panel, the metal thicknesses used on the outer surface can be produced individually and project specific. As the surface metal thickness increases, the bearing capacity increases and, by this way, it increases the life of the sandwich panel.

Sandwich panel lifetime

It is directly proportional to metal thickness since thick metal takes longer to rust and become dysfunctional than thin metal. For this reason, we can say that sandwich panels with thick metal surfaces are more durable.