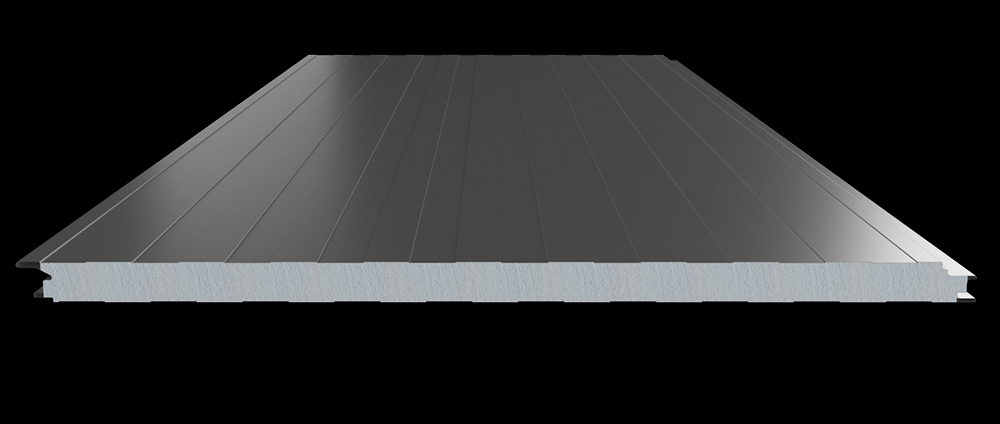

Hidden Screw EPS Facade Panel

PRODUCT DETAIL

EPS insulated facade panel has a solid structure thanks to its double lock feature. Eps insulated facade panels are the most economical sandwich panel facade cladding systems used in facade cladding. Thanks to its B1 fire resistance, it is more beneficial against fire than a polyurethane insulated panel. It can be produced in desired thicknesses.

Eps insulated facade panels are among the most economical facade coating products used among facade panels. The reason for being economical is the eps insulation used in the middle. Eps are extremely healthy isolation products that do not release toxic gas. The eps fuller density in the middle part is 16kg/m3. Thanks to the lightness that this feature brings to the panel, the unit weight of the sandwich panel is lighter.

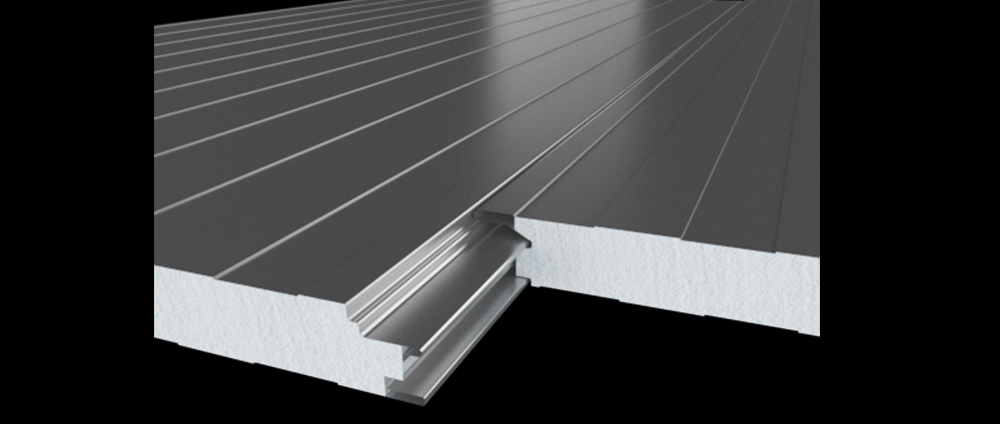

Like other facade panels, EPS-insulated facade panels also have hidden screwing feature. Once the panels are laminated, the screws used to fasten the panels remain hidden. Thanks to its B1 fire resistance feature, it can be used instead of b1 fire class PIR insulation, which is a polyurethane derivative. EPS, which is much cheaper than PIR insulation, offers suitable solutions for some building coating solutions.

There is no need for firing in the Eps facade panel production line. Eps blocks are cut in appropriate thicknesses and adhered between the panel sheet with special adhesives. In the long term, there is no separation or dissolution. They are long-lasting like other polyurethane insulated panels.