5 Ribs Rockwool Insulated Roof Panel

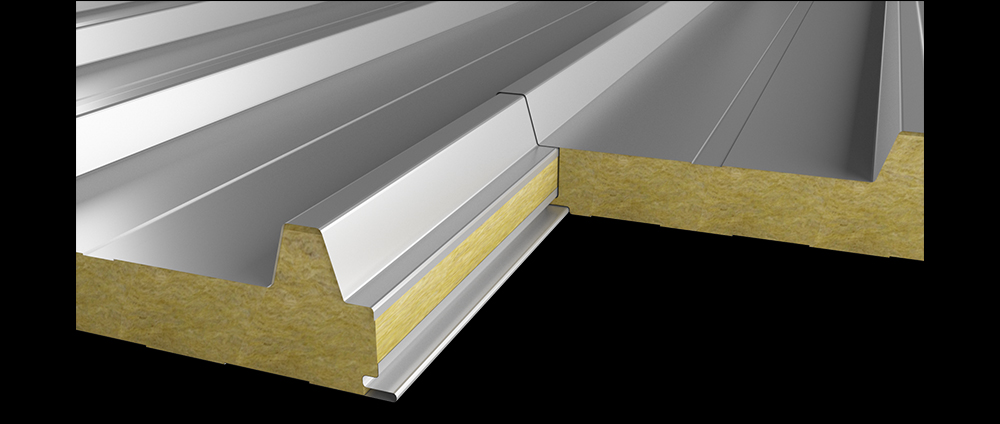

Our panels have 5 ribs in terms of form, and with the double lock feature, both the bottom and the top metal are interlocked. It has a higher load carrying capacity due to its 5 ribs.

PRODUCT DETAIL

The 5-ribbed rockwool-insulated roof panel is 5-ribbed in form.

They are sandwich panel systems consisting of painted galvanized sheet at the top and bottom and rockwool insulation with a density of 100 kg / m3 in the middle. It provides a more rigid fixation of the sandwich panel to the structure, thanks to double lock on the lower and upper lanyards. The double lock prevents the lower metal from sagging over time.

Rockwool insulated roofing panels are the most fire resistant roof systems today. Thanks to the rockwool insulation in its structure, it has a1 class fire resistance. As the thickness of the insulation inside the stone wool roof panel increases, the duration of resistance to fire increases. The 12cm thick rockwool insulated roof panel can resist fire for more than 120 minutes.

Rockwool insulated roof panels have a 5-rib structure. Unlike other polyurethane or polystyrene insulated panels, they do not have 3-ribbed forms.

Rockwool insulated roof panels consist of painted galvanized sheet on the lower and upper surfaces and rock wool insulation with a density of 100kg / m3 in the middle.

Rockwool insulation thickness and metal thickness can be produced in different values according to the project and customer request.

Nowadays, the production of rockwool-insulated roof panels is achieved by slicing the rockwool with machine systems and gluing it to the interior of the panel with special lamination adhesives between the panel.

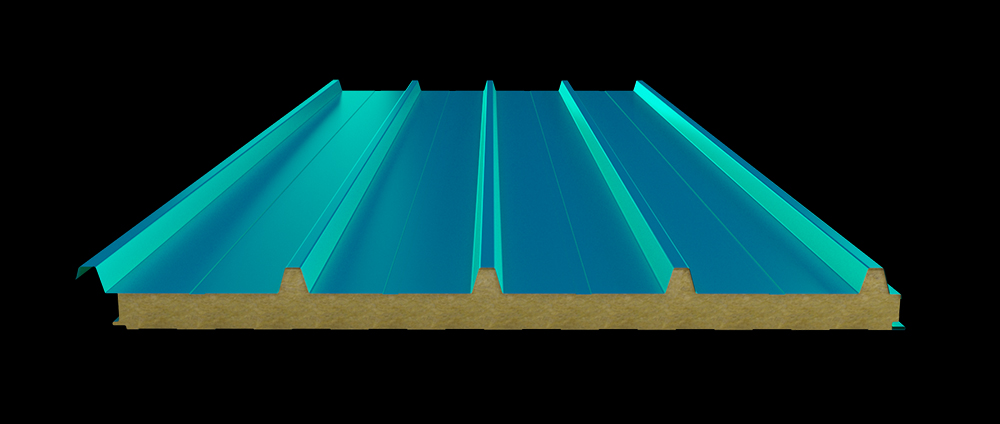

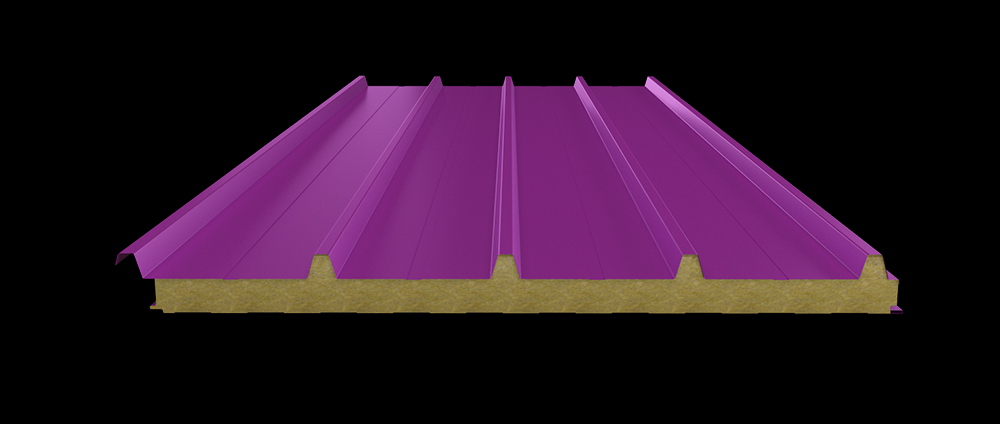

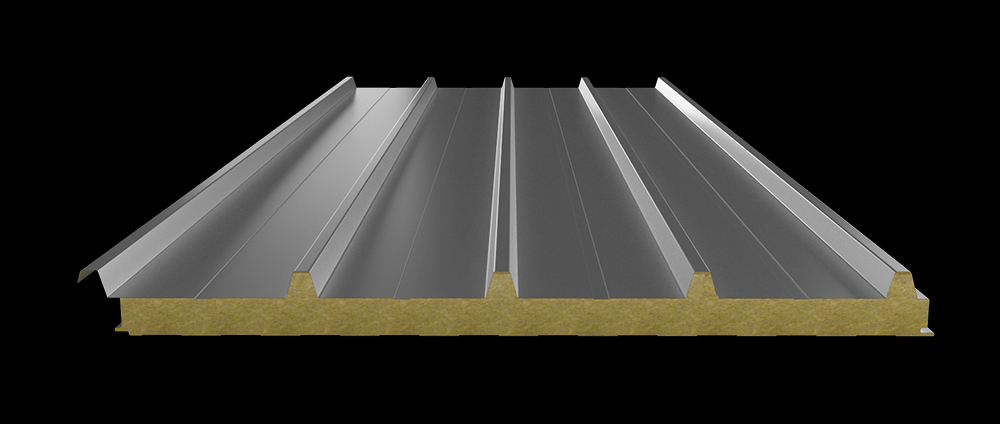

Rockwool insulated roof panels can be produced in special sizes for projects. The color option is limited to the ral chart. Rockwool density used in panel insulation can be adapted according to the project.

Rockwool panels are sensitive panels in terms of structure. One should be careful during installation and while loading and unloading. It is useful to have the assembly process done by an experienced team.

There are special bent panel covers for the mouth parts remaining in the groove parts. Panel covers must be attached to the surface of the panel in the rain gutter after the assembly process is completed. The panel covers are protected from the plant derivatives that can grow inside the rockwool panel due to the nature of the rockwool insulation. One of its key features is that the rockwool insulation absorbs water from the rain gutter over time, so if proper installation is done, it will be prevented and the panels will preserve their structure and feature for many years.

Rockwool insulation, which takes water, may cause the panel to rot from the inside over time and cause the water inside to condense and cause unresolved drops.