3 ribs roof panels pur insulated

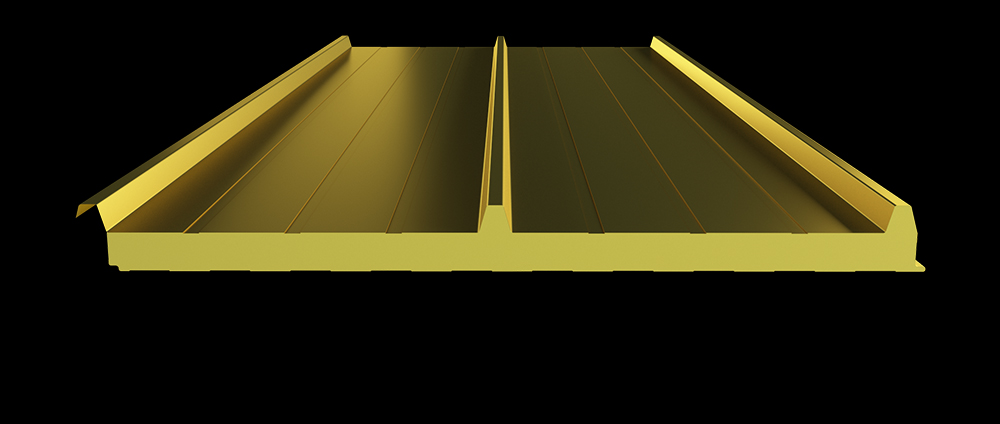

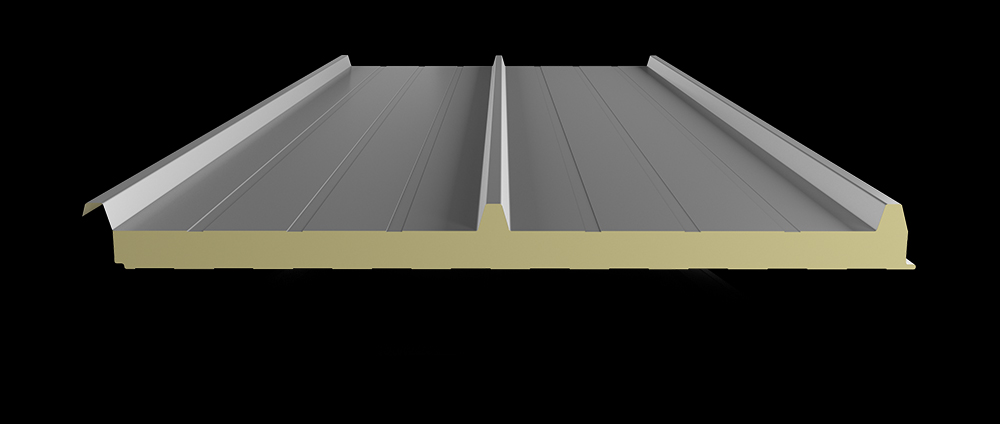

Our panels have 3 ribs in terms of form, and they are two-sided painted galvanized sheet and polyurethane insulated roof panels. Roof panels, which can be produced in 1000 mm widths, are preferred in dense carrier systems and areas with low snow load.

PRODUCT DETAIL

3 ribs polyurethane insulated roof panels are one of the economical solutions used in roof coatings. They are robust and durable sandwich panel systems that are made of galvanized sheet with different thickness bgs on both sides, and polyurethane injected in liquid form in the middle, entering the oven in the production line and taking its final form.

3-ribbed polyurethane insulated sandwich panels are one of the most economical products covering factories, warehouses, shopping malls, airports and residential buildings. Thanks to its 3-ribbed structure, it is easy to clean from the surface area.

3 ribs polyurethane insulated roof sandwich panel systems are sandwich panel systems that are suitable for use in steel construction and concrete prefabricated buildings with less purlins. 3 ribbed polyurethane insulation sandwich panel systems should be preferred in regions with the least snow and wind load.

Since it is a 3-ribbed structure, the weightlifting rate per square meter is low. It is necessary to consider the factors such as snow load, wind load and purlin spacing of the systems to be roofed, and the static calculation of the structure should be made accordingly. These factors are vital in 3 ribbed roof sandwich panel systems.

3 ribs polyurethane insulated roof sandwich panel systems are more economical and lighter than other panels thanks to the low rate of dyed galvanized sheet used due to the low number of ribs. It has turned into a composite structure thanks to the polyurethane insulation it contains in the middle.

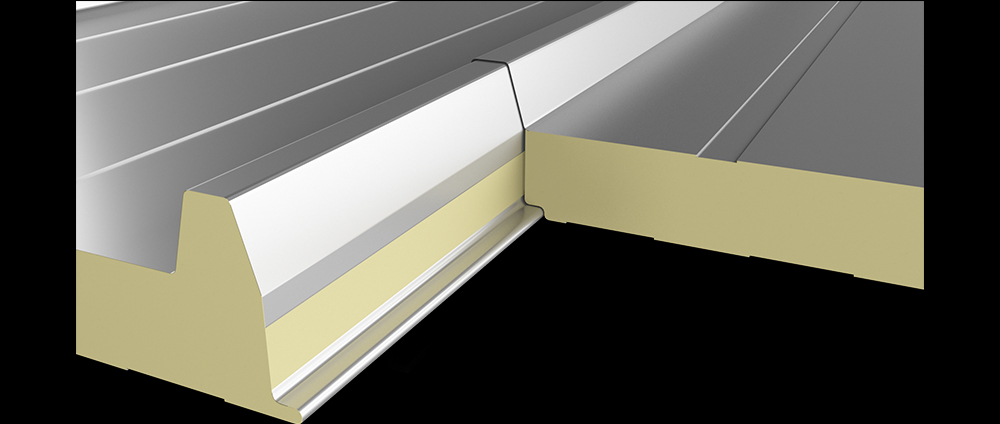

3 ribs polyurethane insulated roof sandwich panel systems are roof panels formed by injecting liquid polyurethane into the oven section when the lower and upper sheet passes through different rolforms and approaches the oven section. These roof sandwich panel systems are fixed using self-drilling screws and saddles. The thickness of the lower and upper metals may differ according to customer demand. As the metal thickness increases, the strength and load carrying capacity of the sandwich panel structure also increases. The greater the metal thickness, the longer the life of the material. 3 ribs polyurethane insulated roof sandwich panel systems are the most widely used sandwich panel roof systems worldwide.